How to Choose the Right Hydraulic Breaker for Your Excavator

In the world of excavation and demolition, the hydraulic breaker is one of the most powerful tools you can add to your fleet. In fact, industry estimates show that up to 30% of all compact excavator tasks involve some form of breaking or demolition work. Whether you're busting through reinforced concrete or chipping away at bedrock, choosing the right hydraulic breaker can dramatically affect your efficiency, fuel use, and machine wear.

What Is a Hydraulic Breaker?

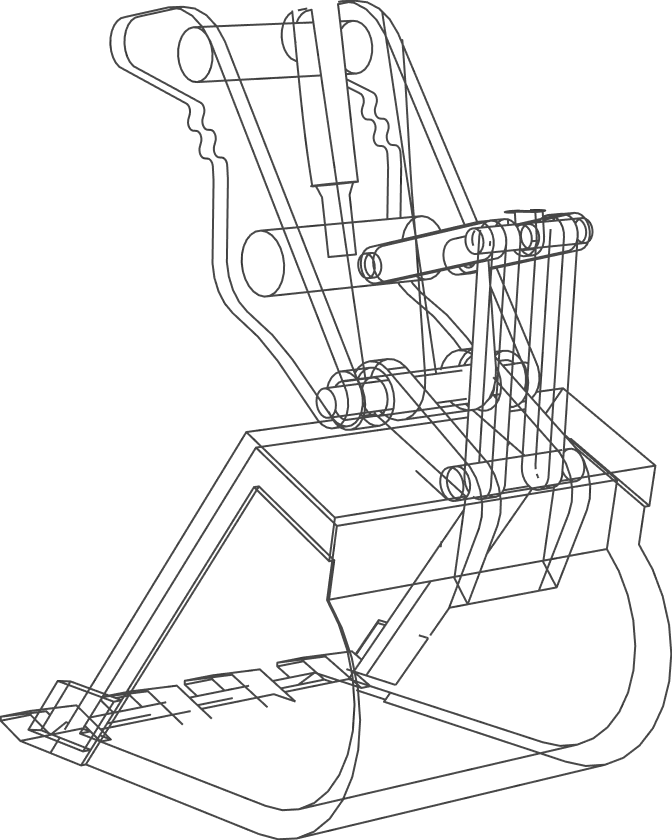

A hydraulic breaker (sometimes called a hammer) is an attachment powered by your excavator’s hydraulic system. It uses pressurized oil to drive a chisel or hammer tool with incredible force. The result? You can demolish concrete, asphalt, rocks, and even frozen ground.

But here’s the thing: not all hydraulic breakers are created equal. Check out our blog comparing Gas-fired vs. Hydraulically fired breakers.

Some are made for all day breaking. Others are built to crush it for a few hours at a time. So how do you pick the right one?

Key Factors When Choosing a Hydraulic Breaker

Let’s look at what matters most when making your selection.

1. Carrier Compatibility

Size matters. Every hydraulic breaker is rated for a specific range of carrier weights. If your breaker is too large for your machine, it can cause excessive stress. Too small, and you’re not getting the force you need.

Match the hydraulic breaker’s operating weight and flow requirements with your carrier’s specifications. Always check both the PSI and GPM your machine can handle.

2. Material Density

Are you breaking concrete? Granite? Maybe frozen soil?

A medium-duty breaker may be perfect for utility trenching or light demolition. For heavy, repetitive tasks—like quarry work or thick concrete—you’ll want a heavy-duty hydraulic breaker with more impact energy.

Quick rule of thumb:

-

Light work: 500-1,000 ft-lb impact energy

-

Medium work: 1,000–3,000 ft-lb

-

Heavy work: 3,000+ ft-lb

3. Tool Type

The tool you use on your hydraulic breaker can change everything. Pointed tools offer precision in tight spots. Blunt tools are great for broad surface impact. Moil points work well for general-purpose demolition.

Keep multiple tool types on hand to adapt to the material and conditions you're working with.

Maintenance and Durability

A hydraulic breaker isn’t a “set it and forget it” tool. It needs care.

1. Lubrication

Use the correct grease every 2 hours—yes, every 2 hours. This reduces heat, lowers friction, and protects your investment. Some breakers come with auto-lube systems. If yours doesn’t, grease it manually before, during, and after use.

2. Inspection

Check the tool bushing, retainer pins, and hoses regularly. Look for wear, leaks, or damage. A small crack can lead to major failure if left unchecked.

3. Storage

When not in use, store your hydraulic breaker vertically and in a dry environment. Keep moisture away. Rust is your enemy.

Matching a Breaker to the Jobsite

Different sites and locations call for different tools. A hydraulic breaker that excels in urban utility work may struggle on a quarry floor. It’s important to stay up-to-date on the equipment you’re using and any new rules and regulations. Typically, silenced breakers are preferred to reduce noise in more densely populated areas.

Urban Jobsites

Look for low-noise or “silenced” hydraulic breakers with vibration dampening. These minimize impact on surrounding structures and reduce operator fatigue.

Remote or Rugged Terrain

Go heavy-duty. Choose breakers with fewer moving parts, higher durability, and longer maintenance intervals.

Tight Spaces

Compact breakers offer the maneuverability needed for indoor demolition or trenching near foundations.

Trust Taurox for the Right Hydraulic Breaker

At Taurox, we know that performance starts with the right equipment. That’s why we offer a curated lineup of high-performance hydraulic breakers engineered for reliability, impact force, and ease of use.

Need help finding the perfect fit? Our experts are here to walk you through compatibility, application, and specs—no guesswork required.

Let’s get you set up with a hydraulic breaker that works as hard as you do. Contact Taurox today and break ground with confidence.