5 Signs It’s Time to Replace Your Excavator Attachment

Your excavator is only as good as the tool on the end of the stick. When your attachment starts slipping, cracking, or slowing you down, it’s more than frustrating; it's costing you time, money, and productivity.

At Taurox, we get it. Most operators push their gear well past its prime not because they want to, but because failure sneaks in slowly. A crack here. A loose fit there. Before long, you’re burning fuel without getting the job done.

Here are five field-proven signs your attachment is holding you back and why upgrading might be the smartest, toughest move you make.

1. Structural Damage That Won’t Stay Fixed

No matter how rugged your job is, a cracked, warped, or beaten-up bucket or thumb is done.

What to watch for:

-

Hairline cracks near welds, pins, or mounting ears

-

Twisted sidewalls, bent tines, or worn cutting edges

-

Back plates pulling away from the body

-

Repairs that last only a few shifts

Our reinforced HardCore™ steel can take a beating but once structural integrity is gone, patch jobs won’t cut it. If you’re welding more than digging, it’s time to upgrade.

2. Loose Fit at the Coupler

An attachment that rocks, rattles, or clunks in the coupler isn’t just annoying it’s a problem.

What it feels like:

-

Excessive “slop” when swinging or digging

-

Pins wearing out faster than normal

-

Constant clunk or chatter under load

Couplers are built to hold tight. If yours don’t anymore, your attachment might be beyond spec and beyond saving.

3. It Just Doesn’t Perform Anymore

Not all wear shows up on the surface. Sometimes it shows lost productivity. Buckets that need extra passes. Thumbs that don’t grip. Rippers that won’t bite. That’s time you’ll never get back.

Signs your tool is underperforming:

-

Buckets not cutting smoothly, leaving material behind, or not filling evenly

-

Teeth shearing off faster than usual

-

Misaligned or sluggish thumb movement

-

More labor for less output

When your attachment stops pulling its weight, the problem isn’t your excavator, it's the tool. Don’t fight it. Replace it.

4. The Job Has Outgrown the Tool

What worked five years ago might be holding you back today. Maybe you’ve got bigger machines, tougher terrain, or new material types.

Time to upsize or upgrade if:

-

Your attachment doesn’t fit your new machine

-

You’re working in demolition, rocky, or frozen ground

-

You’re constantly switching tools to keep pace

This isn’t just a fix, it's an investment in faster, safer, and more efficient work.

5. Repairs Are Getting Too Frequent (and Expensive)

If you’re welding, patching, or swapping parts more than once a season, your repair bills are bleeding you dry.

Ask yourself:

-

How much have I spent on parts and downtime this year?

-

What’s the real cost of lost production?

-

Would a fresh, better-fit tool speed up my day?

At a certain point, repairs become sunk costs. A new build saves time, protects your machine, and keeps your crew productive.

When It’s Time, Taurox Has You Covered

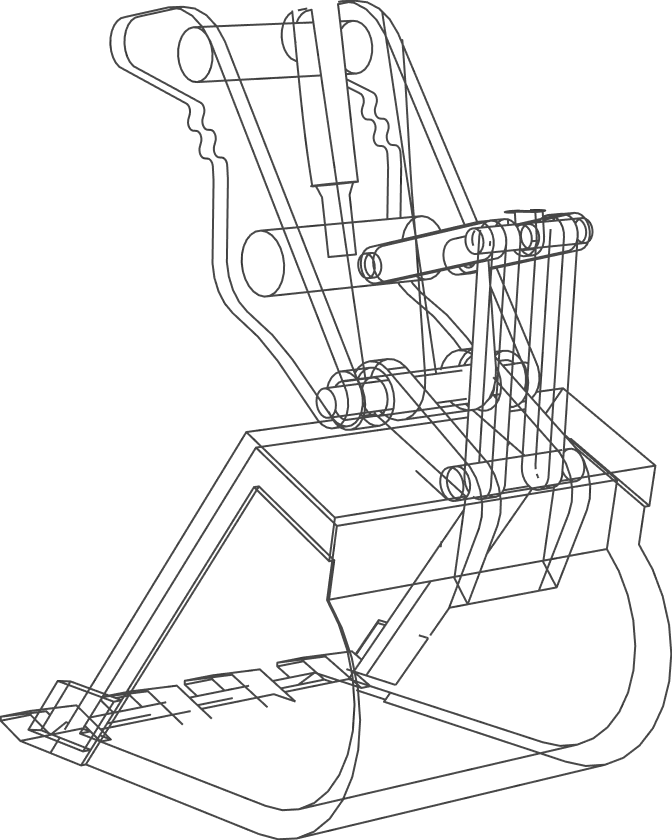

Attachments wear out. That’s a fact. But when yours does, don’t settle. Taurox builds buckets, thumbs, rippers, and more. All engineered for real operators, real machines, and real jobs.

Here’s what sets Taurox apart:

- Get in. Get it Done. - The Taurox team is built for speed.

- Works Harder. Lasts Longer. - Our products are simply built to outperform.

- We back you. Start to finish. - Real Support, no runaround.

- Proudly American - American Born. Built to Perform. Trusted Everywhere.

- Built for the job. Designed by the operators. - Smart Design that Delivers Superior Results

-

3-year durability warranty on every product

If your current attachment costs more than it produces, don’t wait for total failure. We’ll help you spec the right replacement built to work hard and last longer.