Hydraulic-Fired Breakers vs. Gas-Fired Breakers

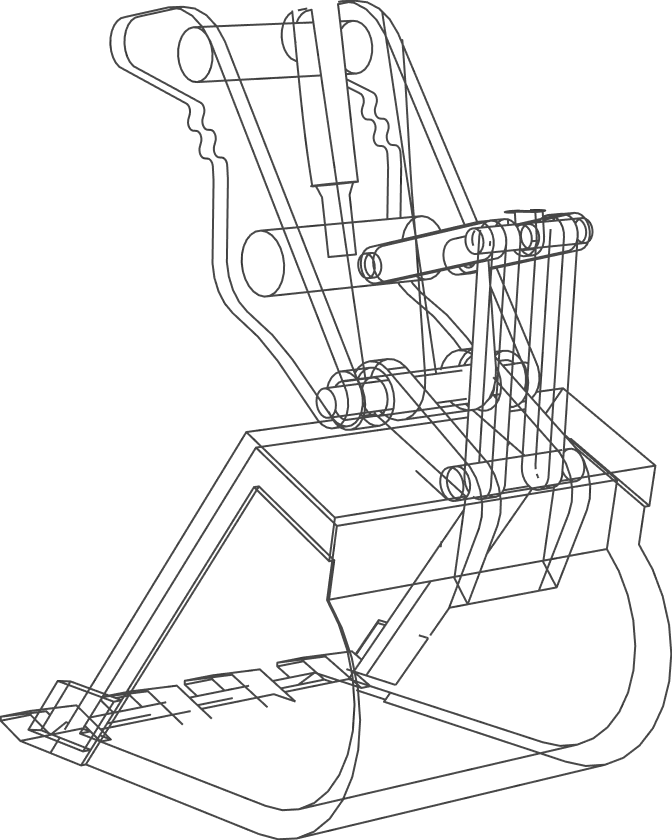

In the world of demolition and excavation, precision matters—and so does power. One of the most important decisions you’ll make when equipping your excavator is choosing between a hydraulic-fired breaker and a gas-fired breaker (also known as a nitrogen-fired breaker). While they may look similar on the outside, the way they generate impact force is fundamentally different.

Let’s break down the mechanics, pros, and cons—so you can make the best choice for your workload, crew, and bottom line.

What’s the Real Difference?

The key distinction lies in how each breaker generates its impact energy. It comes down to this:

-

Hydraulic-fired breakers rely purely on your machine’s hydraulic system.

-

Gas-fired breakers use a combination of hydraulic oil and compressed nitrogen gas.

Simple? Yes. But this single difference influences performance, maintenance, and long-term operating costs in a big way.

Hydraulic-Fired Breakers

How They Work

Hydraulic-fired breakers use your excavator’s hydraulic system as the sole source of energy. The machine’s hydraulic pressure powers a piston that strikes the chisel, delivering impact energy to the material below.

Some models include a nitrogen chamber—not to generate power, but to reduce vibration and wear.

Pros

-

Consistent Performance: Since energy is derived only from hydraulic pressure, you get reliable, steady strikes—even over long periods.

-

Lower Maintenance: With fewer moving parts (and sometimes no nitrogen system at all), these breakers tend to require less maintenance and fewer adjustments.

-

Ideal for Continuous Use: Perfect for trenching, utility work, and other jobs that involve sustained breaker operation.

Cons

-

Lower Impact Energy: Without the additional push from nitrogen, these breakers may not hit as hard per strike.

-

Efficiency Limits: Hydraulic systems alone can be less efficient when it comes to transferring energy into raw breaking force.

Gas-Fired Breakers

How They Work

In a gas-fired breaker, the piston is lifted by hydraulic pressure—just like in hydraulic models. But here’s the kicker: when it’s time to strike, compressed nitrogen gas helps propel the piston downward with greater force.

That added "kick" makes a big difference in tough material conditions.

Pros

-

Higher Impact Force: Nitrogen boosts the downward stroke, making each hit more powerful. Great for concrete, stone, and densely compacted material.

-

Efficient Energy Transfer: You get more bang for your buck—literally.

-

Faster Material Breakage: The increased power can shorten project timelines, especially on demanding sites.

Cons

-

More Maintenance: Nitrogen systems require periodic recharging. More components can also mean more points of failure.

-

Downtime Risk: If the gas charge gets too low mid-job, performance can drop off quickly.

Which One Should You Choose?

Choose a Hydraulic-Fired Breaker if:

-

You prioritize long-term reliability and lower maintenance.

-

Your job involves steady, continuous operation (like trenching or road work).

-

You want a breaker with fewer components and less downtime risk.

Choose a Gas-Fired Breaker if:

-

You’re working with reinforced concrete, bedrock, or extremely hard material.

-

You need maximum impact energy and breaking efficiency.

-

You're okay with a little more maintenance in exchange for power.

Trust Taurox to Help You Break Smarter

At Taurox, we offer both hydraulic-fired and gas-fired breakers—each one carefully engineered for performance, durability, and compatibility with your equipment. Whether you're breaking concrete downtown or busting rock in the field, we can help you choose the right tool for the job.

Not sure what fits your machine or your needs best? Our team is ready to guide you—no pressure, just honest answers.

Contact Taurox today to explore our full lineup of hydraulic breakers and get the most out of every strike.