How to Choose the Right Excavator Bucket for Your Needs

Choosing the right excavator bucket for your machine and application can make all the difference in efficiency, productivity, and equipment longevity. With so many options available, understanding the factors that influence your choice is essential.

1. Consider the Type of Work

The first step in choosing the right bucket is understanding the task at hand. Different buckets are designed for specific purposes:

- Digging buckets: These are the most versatile and widely used. They’re ideal for general excavation, trenching, and earthmoving tasks.

- Clean-up Buckets or Grading buckets: Designed for leveling, backfilling, and fine grading, these buckets have a wider, flat profile for precision work.

- Rock buckets: Built for tough conditions, rock buckets have reinforced edges and teeth to handle abrasive materials and rugged terrain.

- Mini trenching buckets: Narrower and deeper than standard buckets, mini trenching buckets are perfect for creating precise trenches for utility and telecommunication installations and sprinkler line installations.

- By aligning the bucket type with your project’s requirements, you’ll achieve peak performance and reduce wear and tear.

2. Match the Bucket Size to Your Excavator size

The size of your excavator directly impacts the size of the excavator bucket you can use. Buckets that are too large can strain your machine, leading to excessive fuel consumption and mechanical wear. They can also become too heavy for the machine and create a tipping hazard. Conversely, buckets that are too small may slow down progress and lower productivity.

To find the right size, check your excavator’s specifications, including its operating weight, hydraulic capacity, and breakout force. A well-matched bucket ensures efficient operation without compromising safety or equipment performance.

3. Pay Attention to Material Type

The type of material you’re excavating plays a significant role in selecting the right excavator bucket.

- For soft soil or loose materials, standard excavator buckets with minimal reinforcement are often sufficient.

- For rocky or abrasive environments, opt for heavy-duty excavator buckets with reinforced edges and wear-resistant materials.

- For sticky materials like clay, excavator buckets with a curved back or tapered design can prevent clogging and make unloading easier.

4. Look for Wear Protection Features

Excavator buckets endure significant wear, especially in demanding environments. Investing in an excavator bucket with protective features can prolong its lifespan and improve performance. Look for options with:

- Replaceable teeth: This simplifies maintenance and extends your excavator bucket life.

- Wear plates and side cutters: Protect high-stress areas from damage.

- Reinforced corners and edges: Essential for heavy-duty applications like rock excavation.

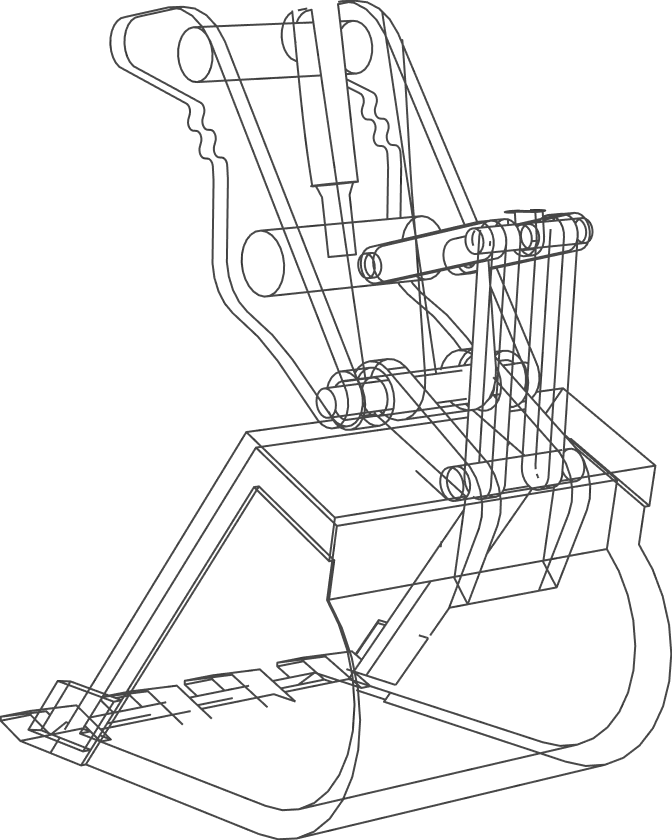

5. Quick Couplers: A Versatile Option

If your projects require switching between multiple excavator buckets or excavator attachments, consider investing in a quick coupler. This attachment allows you to change buckets quickly and safely, minimizing downtime and enhancing productivity.

Why Choose Taurox for Your Excavator Buckets?

At Taurox, we take pride in offering a wide selection of high-quality excavator buckets designed to meet the diverse needs of our clients. Our products are engineered for durability, precision, and performance, ensuring you get the most out of your equipment. Whether you need a standard digging bucket or a specialized rock bucket, our team is here to guide you in making the best choice.

Ready to elevate your excavation game? Explore Taurox’s industry-leading excavator buckets and experience the difference in quality and service. Contact us today to find the perfect excavator bucket for your project.