Why Switching Attachments Faster Boosts Productivity

More than 80% of contractors report job delays due to equipment bottlenecks. And one of the biggest culprits? Slow, outdated processes for switching attachments.

If your crew is spending 15–30 minutes swapping tools multiple times a day, that adds up fast—hours lost per week, per machine. But what happens when that time is cut to just minutes?

Switching attachments faster doesn’t just save time—it transforms productivity across your operation.

The Hidden Cost of Downtime

Minutes Turn Into Hours

Every time you stop the machine to manually change an attachment, you’re doing more than pausing the task—you’re creating ripple effects. The operator waits. The ground crew waits. And sometimes, the entire job pauses.

Let’s say:

-

You spend 20 minutes switching attachments

-

You do it 3 times a day

-

That’s 1 hour lost per day, per machine

-

Over a 5-day week? That’s 5 hours of non-productive time—per machine

Multiply that across a fleet, and the cost becomes impossible to ignore.

Productivity ≠ Speed Alone

Working faster is great. But switching attachments efficiently is really about working smarter. It lets your crew stay in flow, minimize frustration, and keep momentum going throughout the day.

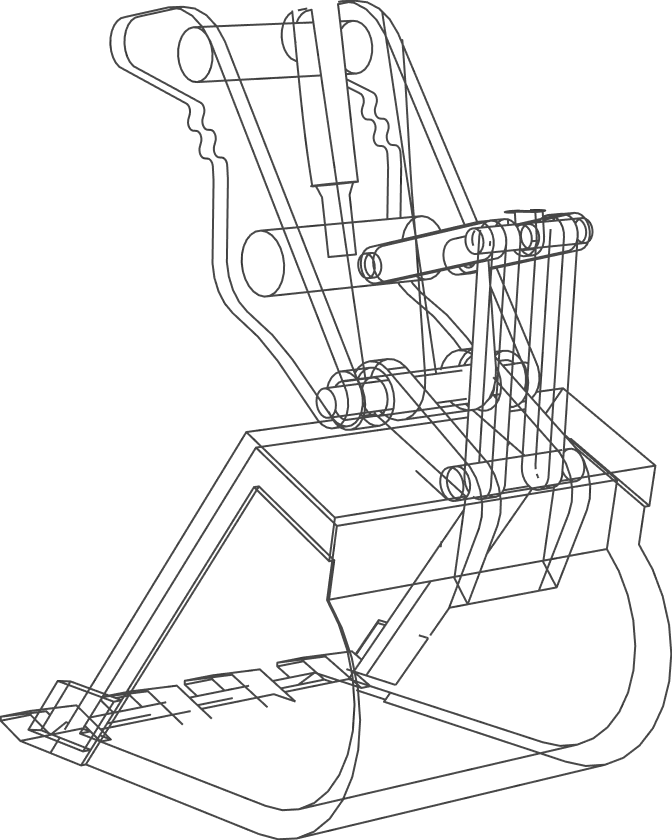

The Power of Quick Couplers

Quick couplers are the unsung heroes of job site productivity. They allow operators to change between buckets, breakers, rippers, grapples, and more—without leaving the cab (in many cases).

Hydraulic Quick Couplers

-

Fastest changeover option

-

Controlled from the cab

-

Ideal for high-frequency attachment changes

Manual Couplers

-

Cost-effective

-

Require manual pin or wedge removal

-

Better suited for applications where changes are infrequent

If your team switches tools multiple times per day, a hydraulic quick coupler can pay for itself in time savings alone within months.

Match the Right Tool to the Right Job—Faster

Imagine trenching with a general-purpose bucket when a trenching bucket would do it cleaner and faster. It happens all the time—not because the right tool isn’t available, but because switching attachments is too time-consuming.

When switching is seamless, you empower your crew to:

-

Use the best tool for each task

-

Minimize wear on equipment by using attachments correctly

-

Deliver cleaner, faster results

It also reduces the temptation to “just make it work” with the wrong tool—because the right one is just a minute away.

Operator Morale and Safety Improve, Too

Less Time Outside the Cab

Manual changes often mean operators exiting the cab repeatedly—climbing on, off, and around the machine. That’s a safety risk, especially on uneven or muddy terrain.

With fast, streamlined attachment switching, operators stay focused, safer, and less fatigued. And happy operators? They stick around.

Real-World Benefits of Faster Attachment Changes

Case Study Snapshots

-

Utility Work: Switching between buckets and compactors multiple times per trench segment becomes smooth and fast.

-

Landscaping: Easily go from grading to digging to debris removal without moving machines or calling for extra help.

-

Demolition: Jump from a breaker to a grapple in under two minutes—minimizing pauses in the demo sequence.

No matter the job, switching attachments quickly keeps the rhythm going.

Trust Taurox for Attachment Efficiency

At Taurox, we know how critical attachment efficiency is. That’s why we design and supply tools built for durability and speed. Whether you're running mini excavators or full-size machines, our couplers and attachments are engineered for fast, secure connections—so your team can focus on production, not processes.

We don’t just build great tools. We build smarter workflows.